The smart Trick of Insulated Spandrel Panel That Nobody is Talking About

Table of ContentsWhat Does Curtain Wall Spandrel Panel Detail Do?Some Of Fire Rated Spandrel PanelFascination About Opaque Spandrel PanelsThe smart Trick of Roof Spandrel Panels That Nobody is Discussing

The units need to be completely put together in a manufacturing facility and also delivered to the site for setup on the structure. The systems are placed on the floors, bundled in pet crates, making use of the tower crane as well as reduced right into location utilizing a smaller crane or hoist had by the glazing specialist. The mullion measurements tend to be somewhat larger than a stick system because of their open area as compared to television form of a common stick drape wall area.

Devices can be set up in a factory while the structural frame of the building is being built. Where stick systems require multiple steps to set up as well as secure the wall surface, unitized wall surfaces arrive on the site completely assembled enabling the floors to be enclosed faster. Unitized systems likewise call for much less area on site for format therefore supplying a benefit for urban sites with area restrictions.

The interlacing vertical mullions will typically have 2 interlacing legs. One leg will remain in the aircraft simply behind the glazing pocket as well as the various other at the indoor face of the mullions. The interlocking leg in the aircraft of the glazing pocket will be sealed by gaskets as well as is the main line of protection versus water as well as air seepage.

Systems whose connecting legs lock likewise endanger the capability of the system to suit motion. Some unitized layouts are delicate to little irregularities in the spacing of surrounding modules; as an example, if the module joints are somewhat out of tolerance, gaskets may not be properly compressed and dampness protection might endure.

Unknown Facts About Fire Rated Spandrel Panel

The four-way intersection refers to the location where 4 adjacent systems meet. This is where field labor need to secure between surrounding devices to attain a weather limited wall. The interlocking legs of the straight mullions are the most crucial user interface of a unitized system. Water that infiltrates the interlocking upright mullions drains pipes to the interlocking horizontals that must collect and also divert this water to the outside.

These upstanding legs have gaskets that seal against the wall surfaces of the bottom horizontal. Some layouts give one good leg that provides one line of defense versus air as well as water seepage. Much more robust systems will provide two upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is installed on top of both adjacent systems as they are erected on the building is normally called for.

The stack joint is the horizontal joint where systems from adjacent floors meet. Positioning the stack joint at the sill of the vision glass (normally 30" above the floor) will certainly minimize the dimension of the upright mullions. This positioning utilizes the back period of the mullion over the anchoring point at the slab to counteract the deflection of the mullion listed below the piece.

While two tale spans are feasible, the weight of the device is doubled which may call for increased structural capacity to suit the increased lots. Wind tons supporting ought to be included at the single period elevation to prevent increasing the upright mullion measurement to fit the increased span. Steel can be Visit Your URL contributed to a unitized system to raise its extending capacity.

Some Known Facts About Nhbc Spandrel Panels.

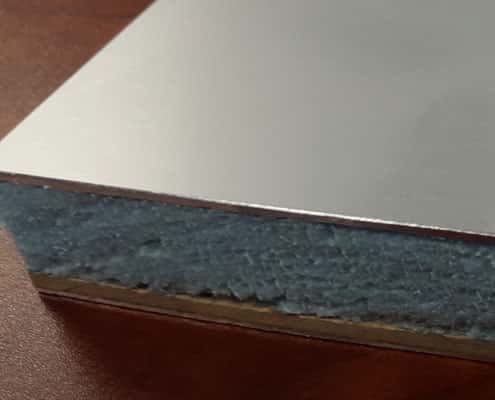

Big systems may also raise transportation prices from the manufacturing facility to the site and erection prices of placing the systems on the structure - opaque spandrel panels. Thermally damaged unitized systems are readily available, making use of similar modern technology as that utilized in stick curtain wall surface systems. The service life of also the most sturdy drape wall might be much shorter than that of resilient nearby wall surface claddings such as rock or block stonework.

The solution life span of elements that are mated with the curtain wall surface right discover this info here into a setting up need to match the life span span of the curtain wall itself. Call for long lasting flashing materials, non-corroding attachment hardware and bolts, as well as moisture resistant materials in regions based on wetting. Laboratory screening: For tasks with a considerable quantity of customized drape wall, require lab testing of a mock-up drape wall before wrapping up job shop drawings.

Define that lab tests are to be conducted at an AAMA Accredited Research laboratory facility. Field Mock-up: For all drape wall surfaces, stock or customized, need construction and also testing of a field mock-up rep of the wall/window assembly. This is ideal arranged prior to the launch of store illustrations for window production, to make sure that there is a possibility to make style changes based on the test performance of the area mock-up.

Area testing of curtain walls: Call for the area screening of drape wall surfaces for air seepage as well as water penetration resistance, for quality control of drape wall surface manufacture as well as setup. opaque spandrel panels. Call for several examinations with the initial examination on preliminary setups and also later examinations at about 35%, 70% and at final completion to catch troubles early and also to verify ongoing craftsmanship top quality.

Top Guidelines Of Insulated Spandrel Panel Detail

Shop attracting coordination: Call for curtain wall surface installment shop drawings showing all surrounding construction as well as window spandrel panel related work, including flashings, accessories, indoor surfaces, as well as showing sequencing of the job. Drape wall surface systems, particularly unitized systems, need knowledge on the part of the building designer, the supplier, the producer, as well as the installer. For just about the most basic of systems, the designer should take into consideration engaging an outdoors professional, if such proficiency is not readily available on the personnel.

The information linked with this section of the BEDG on the WBDG were established by committee and are intended only as a way to illustrate general layout and building and construction principles only. Proper usage and also application of the concepts highlighted in these information will certainly vary based on efficiency considerations and ecological conditions special per task and, for that reason, do not represent the last viewpoint or suggestion of the author of each section or the committee participants responsible for the growth of the WBDG.